Advantages of Fiber Laser Technology

Higher Efficiency:Fiber lasers convert electrical energy into light more efficiently, resulting in lower operating costs and energy consumption.

Enhanced Precision: The fine focus of the fiber laser beam ensures precise and clean cuts, reducing the need for secondary finishing processes.

Speed and Versatility: Fiber lasers can cut through materials at higher speeds and are versatile enough to handle a wide range of thicknesses.

Low Maintenance: With fewer moving parts and a more robust design, fiber laser machines require less maintenance and have a longer operational lifespan.

Safety and Environmentally Friendly: Fiber lasers produce less harmful emissions and are safer to operate compared to older technologies.

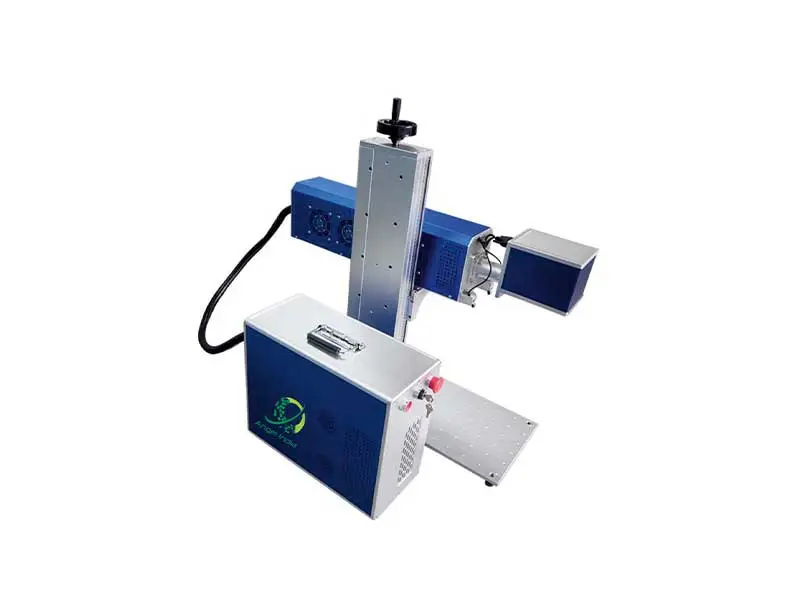

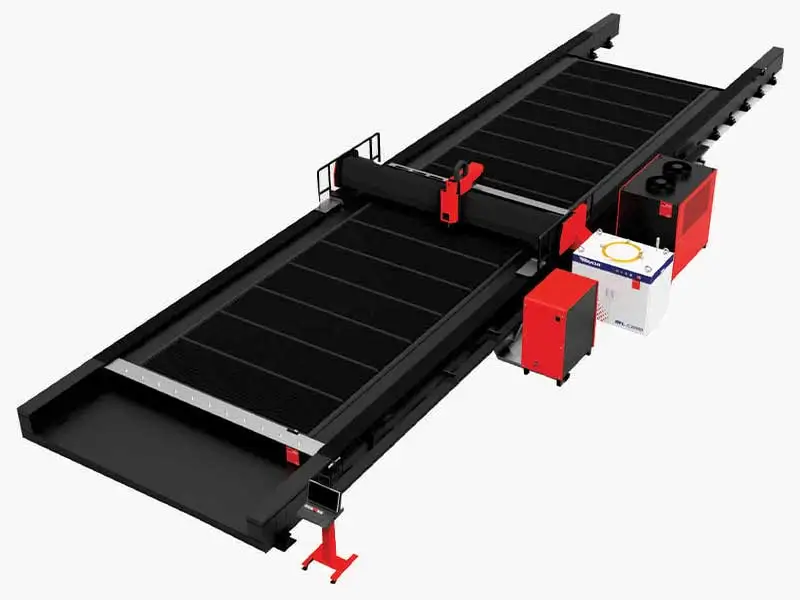

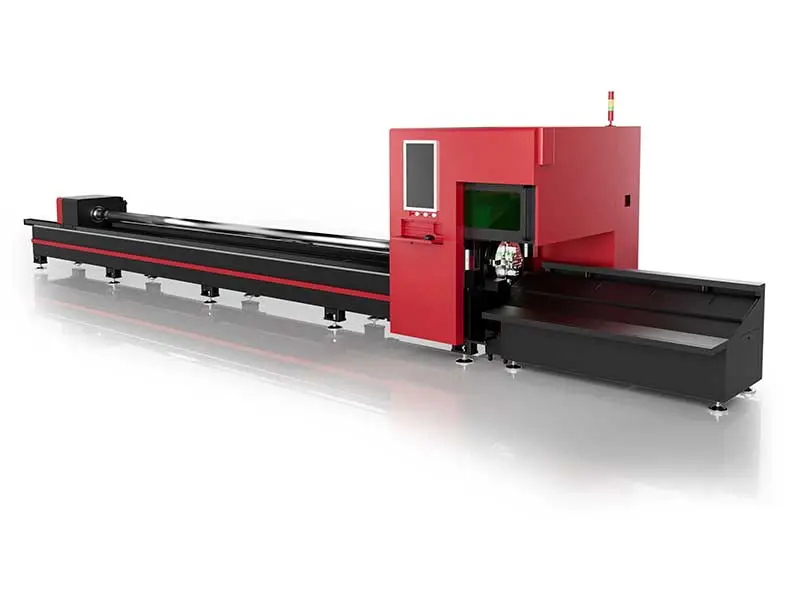

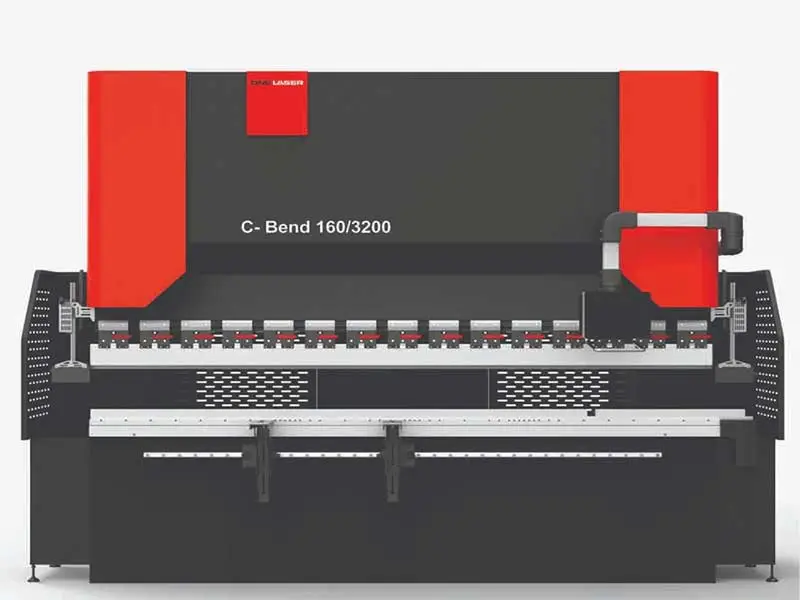

Angel India Cad Cam Pvt. Ltd.'s Fiber Laser Sheet Metal Cutting Machines

Angel India Cad Cam Pvt. Ltd. offers a comprehensive range of fiber laser sheet metal cutting machines designed to meet the diverse needs of its clients. These machines are engineered with precision, incorporating the latest technological advancements to ensure optimal performance and reliability.

Key Features

Advanced Control Systems: The machines are equipped with state-of-the-art control systems that enable precise and efficient operation. The user-friendly interface allows operators to easily set parameters and monitor the cutting process.

High-Power Lasers: Many models come with auDepending on the model, the machines come with high-power fiber lasers capable of cutting through thick materials with ease. The power levels are adjustable to suit different types of metal and cutting requirements.

Automated Features: Fiber lasers have fewer moving parts and a longer operational lifespan compared to traditional CO2 lasers, resulting in lower maintenance requirements and costs.Many models come with automated features such as material loading and unloading systems, which enhance productivity and reduce manual labor.

Safety Measures: Safety is a top priority, and the machines are equipped with multiple safety features, including protective enclosures and emergency stop buttons, to ensure the well-being of operators.

Commitment to Quality and Innovation

Angel India Cad Cam Pvt. Ltd. prides itself on its commitment to quality and continuous innovation. The company invests heavily in research and development to stay ahead of industry trends and to incorporate the latest technological advancements into its products. This dedication to innovation ensures that their fiber laser sheet metal cutting machines remain at the cutting edge of the industry.

Frequently Asked Questions

What materials can be cut using fiber laser sheet metal cutting machines?

Fiber laser sheet metal cutting machines can cut a wide range of materials including stainless steel, carbon steel, aluminum, brass, copper, and other metal alloys.

How do fiber lasers compare to CO2 lasers in terms of efficiency?

Fiber lasers are generally more efficient than CO2 lasers. They convert a higher percentage of electrical energy into laser light, resulting in lower energy consumption and operating costs.

What is the maximum thickness that can be cut with Angel India Cad Cam Pvt. Ltd.'s machines?

The maximum thickness that can be cut depends on the specific model and power of the machine. Typically, high-power fiber laser machines can cut through materials up to 25mm thick.

Are the machines difficult to operate?

No, Angel India Cad Cam Pvt. Ltd.'s machines are designed with user-friendly interfaces and advanced control systems. Operators can easily set parameters and monitor the cutting process, making the machines accessible even to those with minimal training.

What kind of maintenance is required for these machines?

Fiber laser machines require minimal maintenance compared to traditional cutting technologies. Regular maintenance tasks include cleaning the lenses, checking the alignment of the laser beam, and ensuring that all components are functioning correctly. The company provides comprehensive maintenance support to ensure optimal performance.

.webp)

.webp)

.webp)

.webp)

.webp)