Key Features of CO2 Laser Engraving Machines

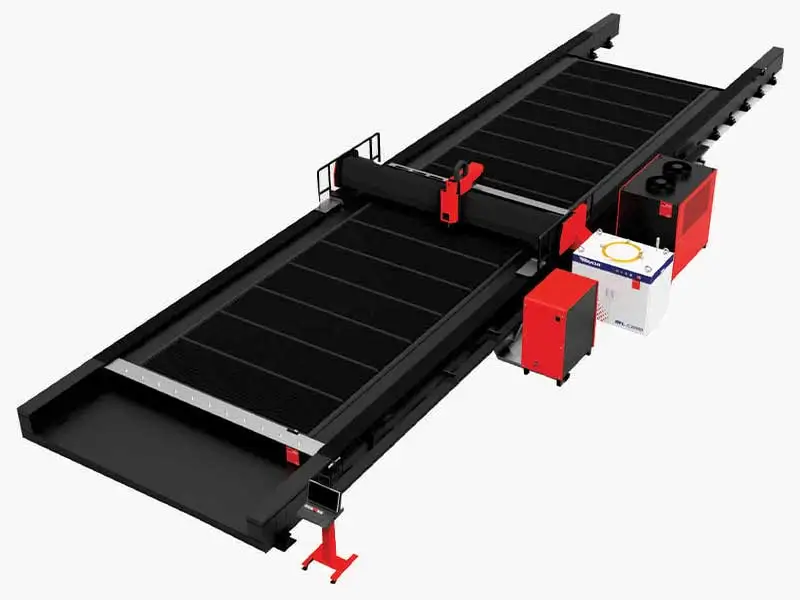

High Precision Engraving: CO2 laser engraving machines are known for their ability to produce high-resolution engravings with exceptional precision. This precision is crucial for applications where intricate designs and fine details are required.

Versatility in Material Compatibility: These machines can engrave a wide range of materials, including wood, acrylic, glass, leather, rubber, textiles, and more. This versatility makes them suitable for various industries and applications.

Speed and Efficiency: CO2 laser engraving machines operate at high speeds, allowing for rapid engraving processes without compromising on quality. This efficiency helps in improving overall production throughput.

Ease of Use and Automation: Many CO2 laser engraving machines are equipped with user-friendly interfaces and automation features. This simplifies operation and setup, reducing the learning curve for operators and enhancing workflow efficiency.

Low Maintenance Requirements: With minimal moving parts and robust design, CO2 laser engraving machines require low maintenance. Regular cleaning and periodic checks ensure consistent performance and longevity of the equipment.

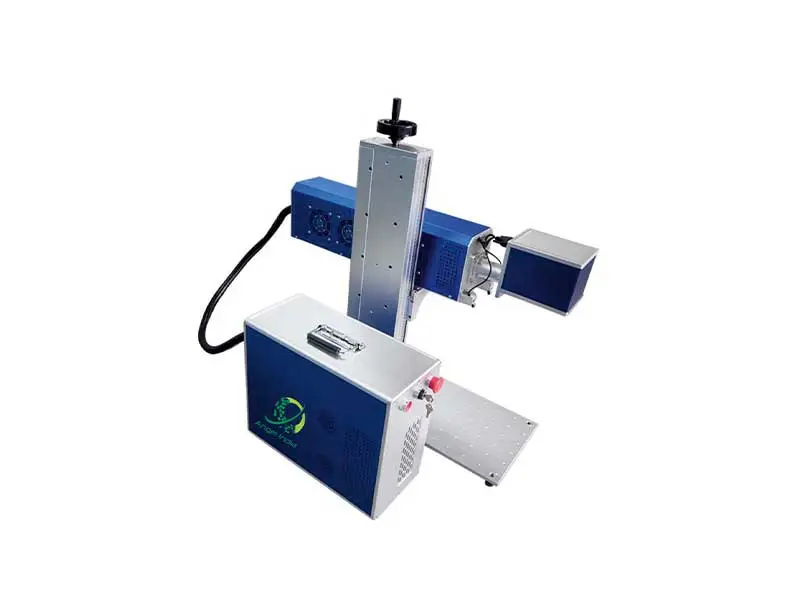

Benefits of Choosing Angel India Cad Cam Pvt. Ltd.

Advanced Technology and Innovation Angel India Cad Cam Pvt. Ltd. stays ahead of the curve by investing in research and development to integrate advanced technologies into their CO2 laser engraving machines. This commitment to innovation ensures that their products are at the forefront of engraving technology, offering clients cutting-edge solutions.

Quality Assurance Quality is paramount at Angel India Cad Cam Pvt. Ltd. The company adheres to stringent quality control measures throughout the manufacturing process, from sourcing materials to final machine assembly and testing. Each CO2 laser engraving machine undergoes rigorous inspection to guarantee optimal performance and durability.

Comprehensive Customer Support Angel India Cad Cam Pvt. Ltd. provides comprehensive customer support services, including installation, training, and ongoing technical assistance. Their team of dedicated professionals ensures that clients receive prompt support and solutions to maximize the efficiency and uptime of their engraving machines.

Customization Options Recognizing the diverse needs of different industries, Angel India Cad Cam offers customization options for their CO2 laser engraving machines. Clients can collaborate with the company's engineers to tailor machines according to specific requirements, ensuring that they meet unique production demands and application needs.

Applications of CO2 Laser Engraving Machines

CO2 laser engraving machines find applications across various industries due to their versatility and precision. Some primary applications include:

Signage and Advertising: Used for engraving logos, text, and graphics on materials like acrylic, wood, and metal for signage and promotional displays.

Woodworking and Furniture: Ideal for engraving intricate designs on wooden surfaces, furniture components, and decorative items.

Textiles and Apparel: Used to create patterns, logos, and designs on fabrics and garments, offering customization and branding capabilities.

Packaging: Engraving serial numbers, barcodes, and labels on packaging materials such as cardboard and plastics for traceability and branding purposes.

Personalization and Gifts:Engraving personalized messages, names, and designs on gifts and keepsakes made from various materials.

Frequently Asked Questions

What materials can be engraved using a CO2 laser engraving machine?

The COCO2 laser engraving machines can engrave a wide range of materials, including wood, acrylic, glass, leather, rubber, textiles, plastics, and metals coated with special engraving coatings.

How What is the maximum thickness of material that a CO2 laser engraving machine can engrave?

The maximum thickness depends on the specific machine's power and configuration. Generally, CO2 laser engraving machines can engrave materials ranging from thin sheets up to several centimeters thick, depending on the laser power and focal length of the lens.

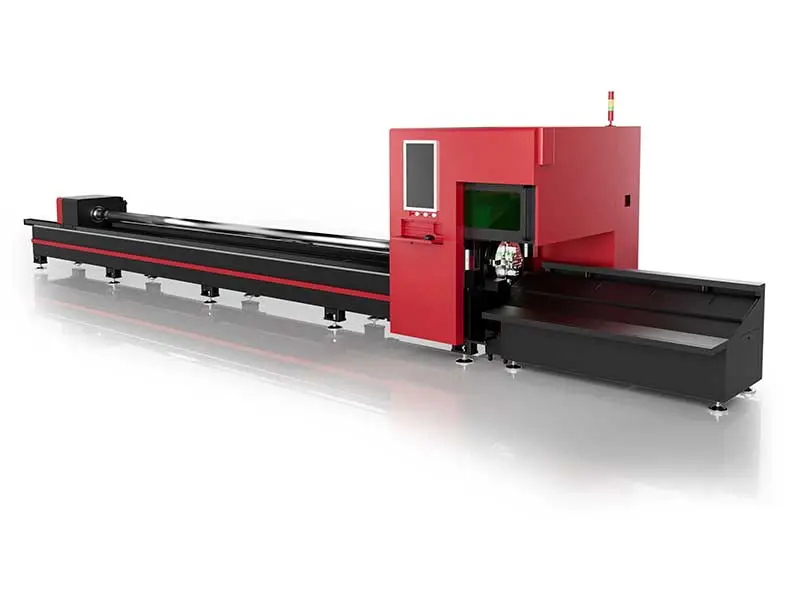

Can CO2 laser engraving machines cut materials as well?

CO2 laser engraving machines are primarily designed for engraving rather than cutting. However, with higher laser power and appropriate settings, some machines can cut thin materials such as paper, cardboard, and thin acrylic sheets.

How do I maintain a CO2 laser engraving machine?

Maintenance of a CO2 laser engraving machine typically involves regular cleaning of optics, checking and replacing consumables like lenses and mirrors, ensuring proper ventilation, and calibrating the machine as needed. Angel India Cad Cam Pvt. Ltd. provides guidelines and support for maintaining their machines.

Are CO2 laser engraving machines safe to use?

When operated according to manufacturer instructions and safety guidelines, CO2 laser engraving machines are safe to use. It's essential to follow safety protocols regarding laser exposure, ventilation in the workspace, and proper machine operation to ensure the safety of operators and bystanders.

.webp)

.webp)

.webp)

.webp)

.webp)