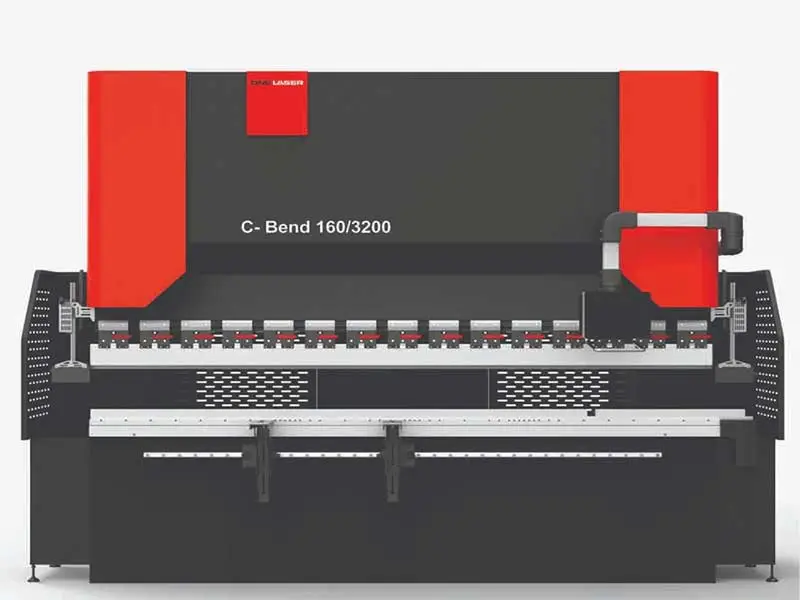

Key Features of CNC Bending Machines

Precision and Accuracy:CNC bending machines offer exceptional precision and accuracy, ensuring consistent and repeatable bends. This precision is crucial in industries where tight tolerances are required.

Advanced Control Systems: The machines are equipped with sophisticated CNC control systems that allow for precise programming of bending operations. These systems enable complex bending tasks to be performed with ease and efficiency.

High-Speed Performance: CNC bending machines are capable of high-speed operations, significantly reducing production time. This efficiency translates into cost savings and increased throughput for businesses.

Versatility:These machines are highly versatile and can handle a wide range of materials, including stainless steel, aluminum, copper, and other metals. This versatility makes them suitable for various applications across different industries.

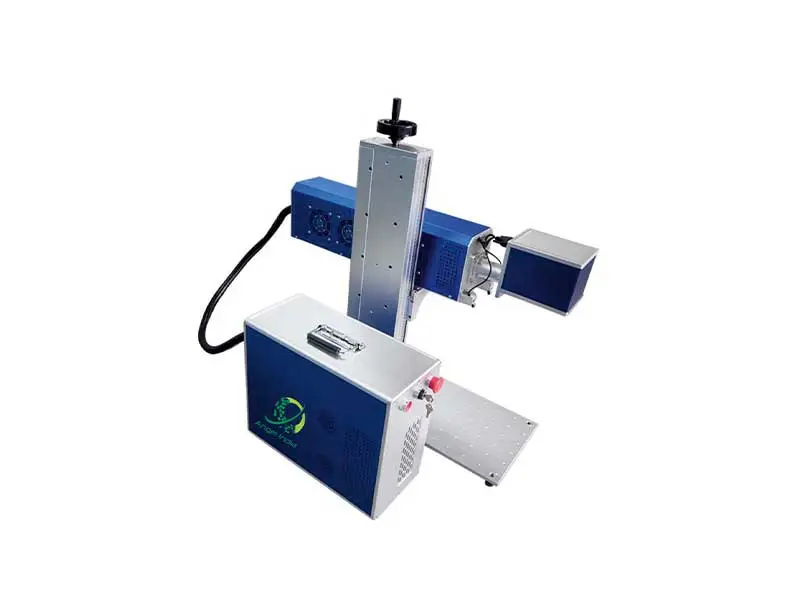

Automation and Integration: Angel India Cad Cam’s CNC bending machines can be seamlessly integrated into automated production lines, enhancing overall operational efficiency. The machines are compatible with various automation systems, allowing for streamlined workflows and improved productivity.

Benefits of Choosing Angel India Cad Cam Pvt. Ltd.

Innovative TechnologyAngel India Cad Cam Pvt. Ltd. is committed to staying at the forefront of technological advancements. The company continually invests in research and development to introduce innovative features and improvements in their CNC bending machines. This commitment to innovation ensures that clients receive the most advanced and efficient bending solutions available.

Quality Assurance Quality is a cornerstone of Angel India Cad Cam’s operations. The company adheres to strict quality control measures at every stage of the manufacturing process, from the selection of raw materials to the final inspection of the finished product. This meticulous attention to detail guarantees that each CNC bending machine meets the highest standards of quality and performance.

Customer Support and Service Angel India Cad Cam Pvt. Ltd. places a strong emphasis on customer satisfaction. The company offers comprehensive support services, including installation, training, and maintenance. Their dedicated customer support team is always available to assist clients with any issues or queries, ensuring a smooth and hassle-free experience.

Customization Options Understanding that different industries have unique requirements, Angel India Cad Cam provides customization options for their CNC bending machines. Clients can work closely with the company’s engineers to develop tailored solutions that meet their specific needs and objectives.

Competitive Pricing Despite offering advanced technology and superior quality, Angel India Cad Cam Pvt. Ltd. ensures that their products are competitively priced. This approach makes high-end CNC bending machines accessible to a broader range of businesses, allowing them to benefit from the latest bending technology without compromising their budget.

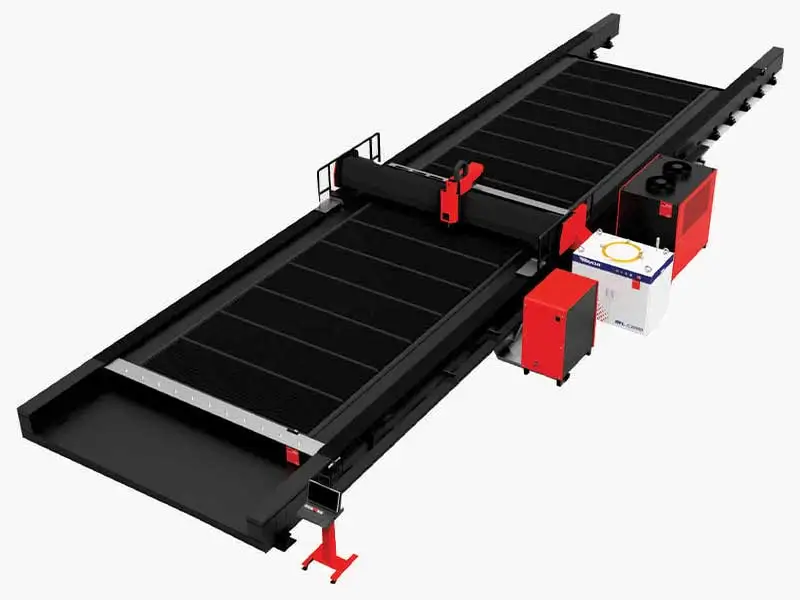

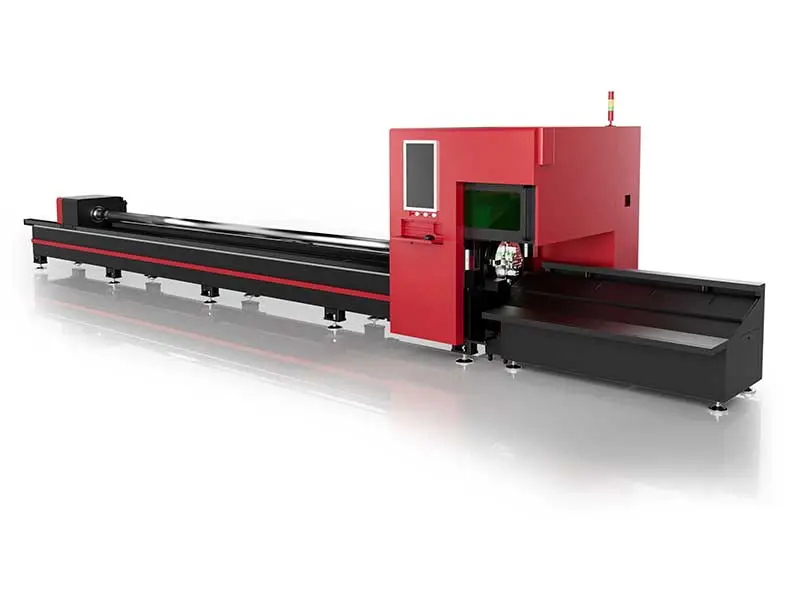

Applications of CNC Bending Machines

CNC bending machines from Angel India Cad Cam Pvt. Ltd. find applications in various industries due to their versatility and efficiency. Some of the primary applications include:

Automotive Industry: Used for bending metal components such as chassis parts, exhaust systems, and structural frames. The precision and speed of CNC bending improve production efficiency and product quality.

Aerospace Industry: Essential for bending aircraft components that require high precision and minimal distortion. CNC bending ensures strong and reliable parts in aerospace applications.

Construction Industry: Applied in the fabrication of structural elements, frames, and support beams. The ability to handle large and heavy materials makes CNC bending machines invaluable in construction.

Manufacturing Industry: Used in the production of machinery, tools, and equipment. The versatility of CNC bending makes it suitable for a wide range of manufacturing applications.

Frequently Asked Questions

What materials can be bent using a CNC bending machine?

CNC bending machines are highly versatile and can bend a wide range of materials, including stainless steel, aluminum, copper, and other metals. This versatility allows them to be used in various applications across different industries.

What are the main advantages of CNC bending over traditional bending methods?

CNC bending offers several advantages over traditional bending methods, including higher precision, faster bending speeds, advanced control systems, automation capabilities, and the ability to handle complex bending tasks. These benefits result in improved productivity, cost savings, and consistent quality.

How do I maintain a CNC bending machine?

Maintaining a CNC bending machine involves regular inspection and cleaning of the machine components, lubrication of moving parts, checking and replacing consumables, and ensuring proper alignment and calibration. Angel India Cad Cam Pvt. Ltd. provides comprehensive maintenance support to ensure the longevity and optimal performance of their machines.

Can CNC bending machines be customized to meet specific requirements?

Yes, Angel India Cad Cam Pvt. Ltd. offers customization options for their CNC bending machines. Clients can work with the company’s engineers to develop tailored solutions that meet their specific needs and objectives, ensuring that the machines are perfectly suited to their production requirements.

What industries benefit the most from using CNC bending machines?

CNC bending machines are beneficial in various industries, including automotive, aerospace, construction, manufacturing, and furniture. The precision, speed, and versatility of these machines make them suitable for a wide range of applications across different sectors.

.webp)

.webp)

.webp)

.webp)

.webp)