Product Range

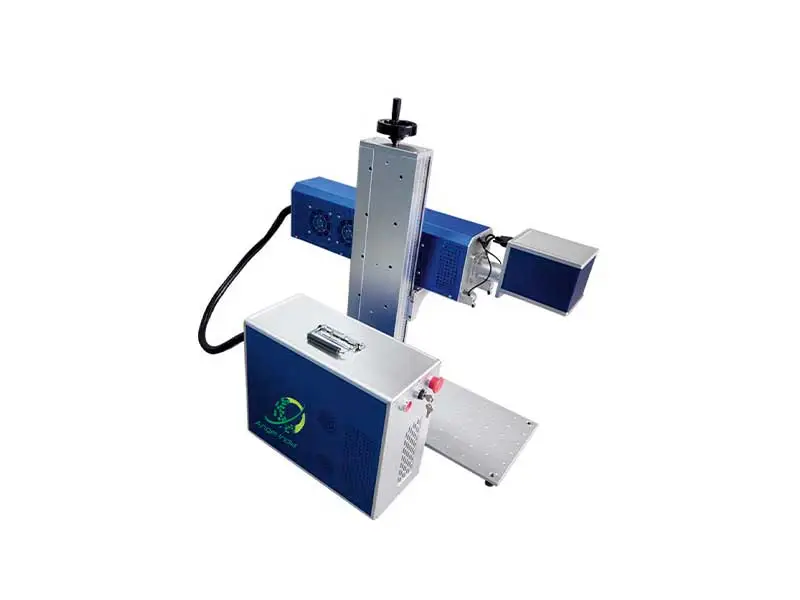

Angel India Cad Cam Pvt. Ltd. offers a diverse range of laser hallmarking machines designed to cater to various industry needs. These machines are known for their robustness, accuracy, and user-friendly interface. Here are some of the flagship products:

AI-LHM-150: This entry-level laser hallmarking machine is perfect for small to medium-sized enterprises. It offers precise marking capabilities with a compact design that fits easily into smaller workspaces.

AI-LHM-300: A step up from the AI-LHM-150, this model provides enhanced speed and versatility. It’s suitable for larger operations and can handle a higher volume of hallmarking tasks with ease.

AI-LHM-500: This high-performance machine is designed for industrial-scale operations. It offers the fastest marking speeds and the highest precision, making it ideal for large manufacturers.

AI-LHM-Gold: Specifically tailored for the jewelry industry, this machine ensures that gold items are marked with utmost precision. Its advanced features prevent any damage to delicate pieces.

Advantages of Laser Hallmarking

Laser hallmarking has emerged as the preferred method for marking metals due to its numerous advantages:

Precision: Laser hallmarking offers unparalleled precision, ensuring that even the smallest details are marked accurately. This is particularly important in the jewelry industry, where intricate designs are common.

Speed: Laser technology allows for fast marking, significantly reducing the time required for each piece. This efficiency is crucial for large-scale operations.

Durability: Marks made by laser are permanent and resistant to wear and tear. This ensures that hallmarks remain legible for the lifetime of the product.

Versatility: Laser hallmarking can be used on a variety of materials, including gold, silver, platinum, and other metals. This versatility makes it a valuable tool for different industries.

Impact on the Industry

Angel India Cad Cam Pvt. Ltd. has had a profound impact on the laser hallmarking industry. By providing reliable and advanced solutions, the company has helped businesses improve their productivity and quality. Jewelers, in particular, have benefited from the precision and efficiency of Angel India’s machines, allowing them to meet stringent quality standards and regulatory requirements.

The company’s commitment to customer satisfaction extends beyond product delivery. Angel India provides comprehensive after-sales support, including training, maintenance, and technical assistance. This ensures that customers can maximize the potential of their machines and minimize downtime.

Frequently Asked Questions

What is laser hallmarking, and why is it important?

Laser hallmarking is a process that uses laser technology to mark metals with identifying marks or logos. It is crucial for verifying the authenticity and purity of metals, particularly in the jewelry industry, where hallmarking ensures that items meet regulatory standards.

How does Angel India Cad Cam Pvt. Ltd. ensure the quality of its machines?

Angel India Cad Cam Pvt. Ltd. invests heavily in research and development to incorporate the latest technology into its machines. Each machine undergoes rigorous testing and quality checks to ensure it meets the highest standards of performance and durability.

What industries can benefit from Angel India’s laser hallmarking machines?

While the jewelry industry is the primary beneficiary, other industries, such as manufacturing, electronics, and automotive, can also benefit from the precision and efficiency of laser hallmarking machines.

What kind of support does Angel India offer to its customers?

Angel India provides comprehensive after-sales support, including training for operators, regular maintenance services, and technical assistance. This ensures that customers can operate their machines efficiently and address any issues promptly.

Can Angel India customize laser hallmarking machines to meet specific needs?

Yes, Angel India Cad Cam Pvt. Ltd. offers customized solutions tailored to meet the unique requirements of different businesses. Their team works closely with clients to design and develop machines that address specific operational challenges and maximize productivity.

.webp)

.webp)

.webp)

.webp)

.webp)