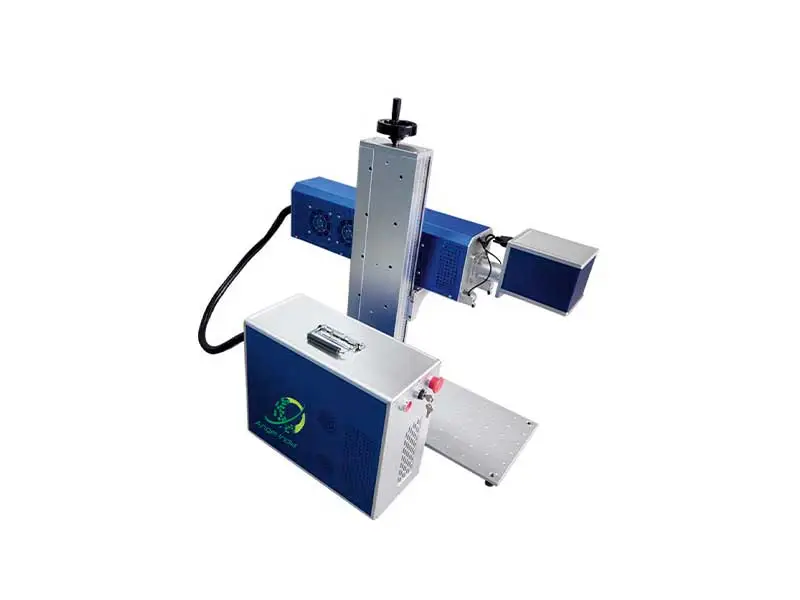

Non-contact Process:Unlike traditional marking methods, CO2 laser marking is non-contact, eliminating the risk of material deformation and ensuring clean, permanent marks.

Speed and Efficiency: These machines operate at high speeds, facilitating rapid production cycles and enhancing overall productivity.

Low Maintenance:With fewer moving parts and a sealed CO2 laser source, maintenance requirements are minimal, reducing downtime and operational costs.

Industries Served

Angel India Cad Cam Pvt. Ltd. caters to various industries including:

Electronics: Marking and engraving on electronic components for identification, branding, and traceability.

Automotive: Engraving on automotive parts and components for identification, traceability, and branding purposes.

Medical Devices: Marking on medical devices and instruments to ensure compliance with regulatory standards and for identification purposes.

Jewelry and Ornaments:Precise engraving on jewelry and decorative items to create intricate designs and patterns.

Customer-Centric Approach

Angel India Cad Cam Pvt. Ltd. places a strong emphasis on customer satisfaction. The company’s customer-centric approach is evident in its comprehensive support services, which include:

Manufacturing: Marking of serial numbers, logos, and part numbers on metal and plastic components.

Electronics: Identification and traceability marking on PCBs, connectors, and semiconductor devices.

Medical Devices: FDA-compliant marking on surgical instruments, implants, and medical equipment.

Automotive: VIN marking, branding, and part identification on automotive components.

Packaging: Batch coding, expiration dates, and barcodes on packaging materials.

Customization and Integration

The company offers customizable solutions tailored to specific customer requirements, including integration with existing production lines and automation systems. Their expertise in laser technology ensures seamless integration and optimized performance.

Customer Support and Service

Angel India Cad Cam Pvt. Ltd. prioritizes customer satisfaction with comprehensive after-sales support, including training, maintenance services, and technical assistance. Their dedicated team of experts ensures that clients receive prompt assistance and maximize the uptime of their equipment.

Frequently Asked Questions

What materials can be marked with CO2 laser machines?

CO2 laser marking machines can mark a wide range of materials including metals (stainless steel, aluminum), plastics, ceramics, glass, wood, leather, and certain coated materials.

How durable are the marks made by CO2 lasers?

Marks made by CO2 lasers are highly durable and resistant to fading, abrasion, and chemicals, making them suitable for industrial applications requiring long-lasting identification.

What are the advantages of CO2 laser marking over other methods?

CO2 laser marking offers advantages such as high precision, non-contact marking, fast processing speeds, and minimal maintenance compared to methods like inkjet printing or mechanical engraving.

Can CO2 laser marking machines handle large-scale production requirements?

Yes, CO2 laser marking machines are scalable and can be integrated into high-volume production lines, offering consistent quality and efficiency even under demanding manufacturing conditions.

Is training provided for operating CO2 laser marking machines?

Angel India Cad Cam Pvt. Ltd. provides comprehensive training programs for operators and maintenance personnel to ensure safe and efficient operation of their CO2 laser marking machines.

.webp)

.webp)

.webp)

.webp)

.webp)