What materials can your laser cutting machines handle?

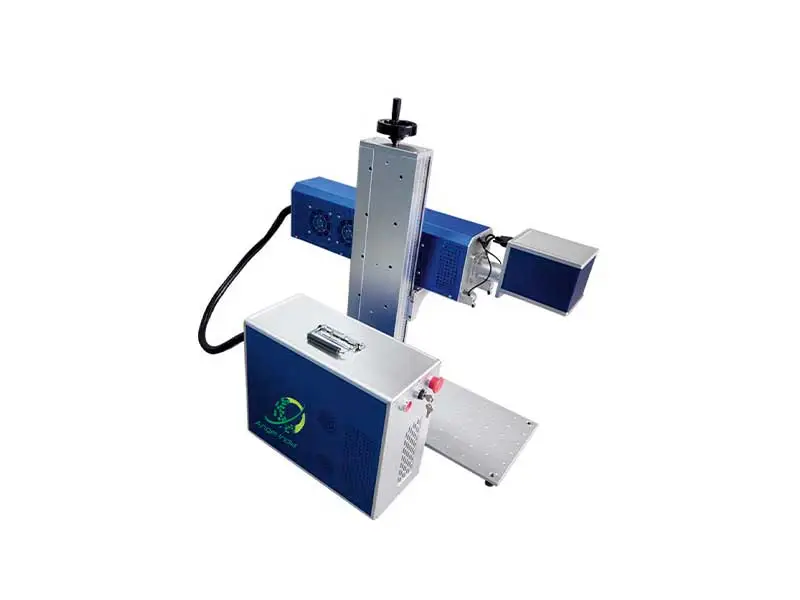

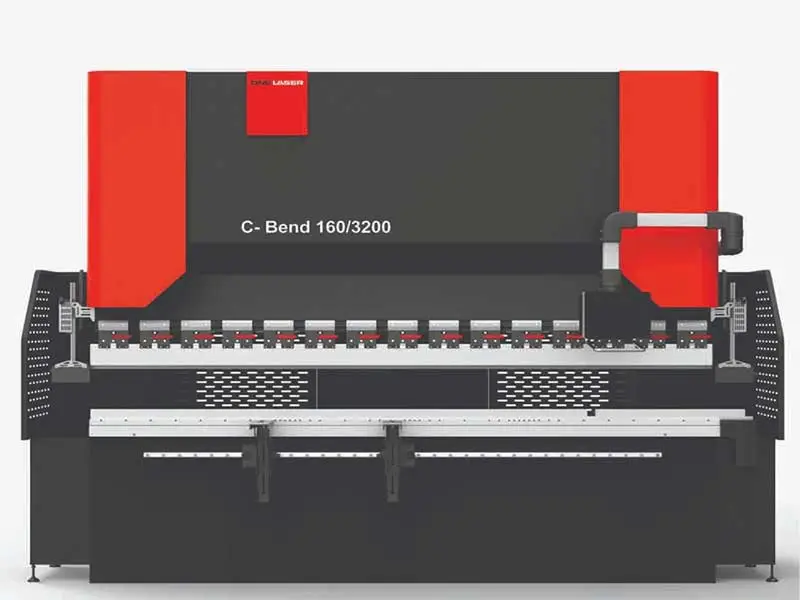

Our laser cutting machines are highly versatile and can handle a wide range of materials, including metals (steel, aluminum, copper), plastics, wood, glass, and more. This makes them suitable for various industries such as automotive, aerospace, electronics, and jewelry.

How do you ensure the quality of your laser cutting machines?

Quality is a top priority for us at Angel India Cad Cam Pvt. Ltd. We implement stringent quality control measures throughout the manufacturing process, from sourcing raw materials to final assembly and testing. Our machines undergo rigorous inspections and testing to ensure they meet the highest standards of performance and reliability.

What kind of after-sales support do you offer?

We offer comprehensive after-sales support to ensure our customers get the most out of their laser cutting machines. This includes installation, training, and maintenance services. Our team of skilled technicians is always available to assist with any issues or queries, ensuring that your machine operates at peak performance.

Can your laser cutting machines be customized to specific requirements?

Yes, we understand that different industries and applications have unique requirements. Our R&D team works closely with clients to develop customized solutions that address specific challenges and needs. Whether it's modifying the machine's configuration or developing new features, we are committed to delivering tailored solutions.

What safety features are incorporated into your laser cutting machines?

Safety is paramount in our design and manufacturing process. Our laser cutting machines are equipped with advanced safety mechanisms, including protective enclosures, emergency stop buttons, and automated shutdown features. These safety measures ensure that operators are protected and that the machines operate safely under all conditions.

.webp)

.webp)

.webp)

.webp)

.webp)