What is laser jewelry welding, and how does it differ from traditional welding methods?

Laser jewelry welding utilizes focused laser beams to create precise welds between metal components without the need for filler materials. This differs from traditional methods like soldering, which may involve additional materials and heat that can affect delicate jewelry components.

What are the advantages of using a laser jewelry welding machine?

Laser jewelry welding machines offer several advantages, including high precision, minimal heat-affected zones, non-contact welding, capability to weld complex geometries, and the ability to work with a variety of metals and alloys commonly used in jewelry making.

Can laser welding machines handle different types of jewelry materials?

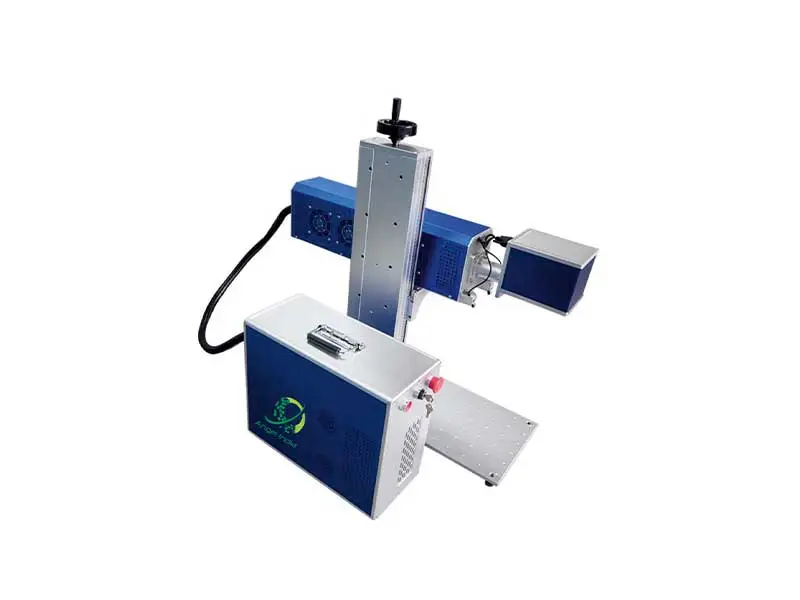

Yes, laser welding machines from Angel India Cad Cam Pvt. Ltd. are designed to handle a wide range of jewelry materials, including gold, silver, platinum, palladium, titanium, and their alloys. The parameters can be adjusted to suit the specific characteristics of each material.

Are laser welding machines suitable for both production and repair of jewelry?

Yes, Angel India Cad Cam's laser welding machines are versatile and suitable for both production of new jewelry pieces and repair/restoration of existing jewelry items. They facilitate seamless integration and precise welding even in intricate and delicate settings.

What kind of support does Angel India Cad Cam Pvt. Ltd. offer after purchasing a laser jewelry welding machine?

Angel India Cad Cam Pvt. Ltd. provides comprehensive support services, including installation, training on machine operation and maintenance, troubleshooting assistance, and access to spare parts. The company is committed to ensuring its customers maximize the uptime and efficiency of their laser welding machines.

.webp)

.webp)

.webp)

.webp)

.webp)