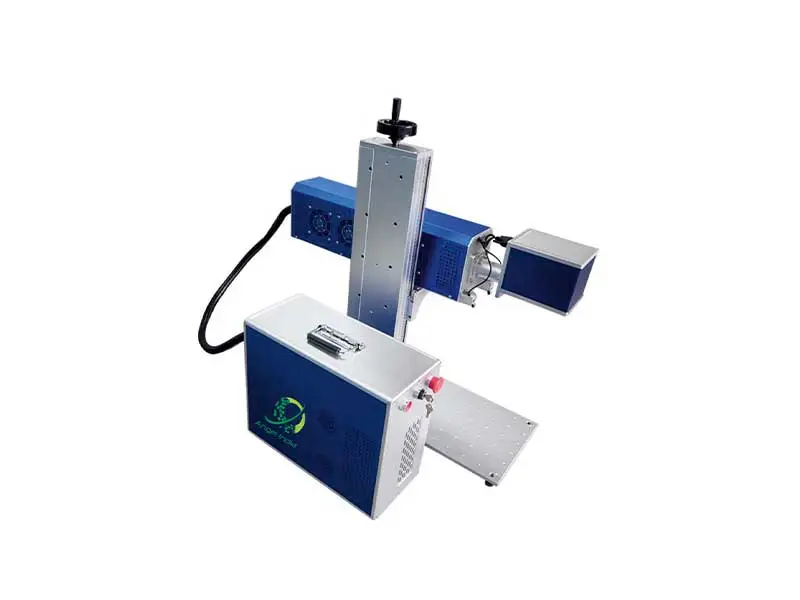

Key Features of Angel India Cad Cam Pvt. Ltd.’s Fiber Laser Glass Cutting Machines:

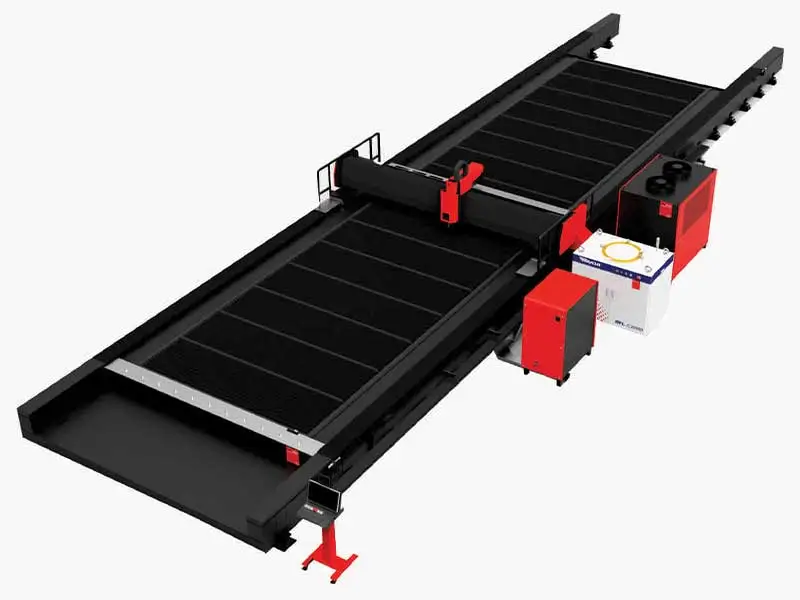

Speed and Efficiency: These machines are designed for high-speed operations, significantly reducing cutting times and enhancing productivity.

High Precision: The fiber laser technology provides precise control over the cutting process, ensuring clean and accurate cuts.

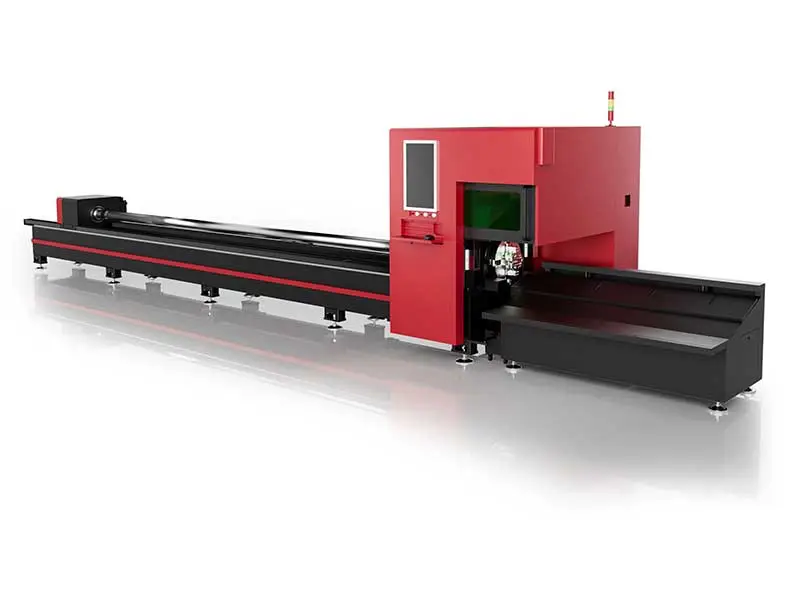

Versatility: Capable of cutting various types of glass, including tempered, laminated, and borosilicate glass.

Durability and Reliability: Constructed with high-quality components, these machines are built to last and deliver consistent performance.

Applications of Fiber Laser Glass Cutting Machines

The versatility of Fiber Laser Glass Cutting Machines from Angel India Cad Cam Pvt. Ltd. makes them suitable for a wide range of applications across various industries. Some key applications include:

Automotive Industry: Cutting and shaping automotive glass components with high precision and minimal waste.

Architectural Glass: Architects and builders use fiber laser cutting to create custom glass elements for buildings, such as windows, doors, and decorative panels. The ability to produce detailed and unique designs enhances the aesthetic appeal of architectural projects.

Electronics: Cutting glass components for electronic devices, such as screens and touch panels, with intricate detail and accuracy.

Architecture and Construction: Creating custom glass panels and designs for architectural applications.

Medical Devices:Producing precise glass components for medical devices and instruments.

Decorative Arts: Cutting intricate designs and patterns on glass for decorative and artistic purposes.

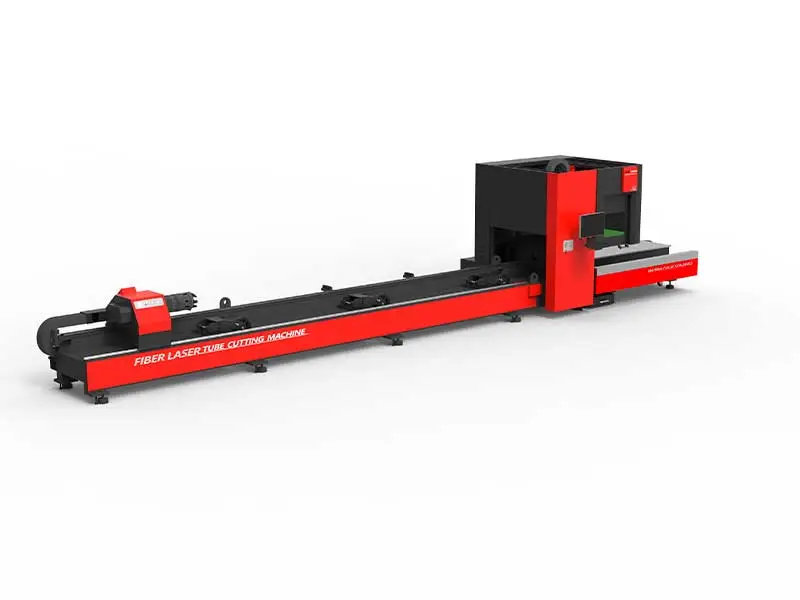

Manufacturing Excellence

Angel India Cad Cam Pvt. Ltd. prides itself on its meticulous manufacturing process, which adheres to the highest standards of quality and precision. The company employs state-of-the-art technology and a skilled workforce to produce Fiber Laser Glass Cutting Machines that meet and exceed industry expectations.

Steps in the Manufacturing Process:

Design and Engineering: Detailed design and engineering processes ensure that each machine meets specific requirements and industry standards.

Material Selection: High-quality materials are chosen to ensure durability and optimal performance.

Precision Fabrication:Advanced fabrication techniques are used to create components with exceptional accuracy.

Quality Testing:Rigorous testing procedures are conducted to verify the performance, accuracy, and reliability of the machines before they are delivered to customers.

Commitment to Sustainability

In addition to its focus on innovation and quality, Angel India Cad Cam Pvt. Ltd. is also committed to sustainability. The company incorporates eco-friendly practices in its manufacturing processes and strives to create machines that minimize environmental impact. By promoting efficient and sustainable manufacturing methods, Angel India Cad Cam Pvt. Ltd. is contributing to a greener future.

Frequently Asked Questions

What is a Fiber Laser Glass Cutting Machine and how does it work?

A Fiber Laser Glass Cutting Machine uses a high-powered fiber laser to cut through glass with precision. The laser emits a concentrated beam of light that melts and vaporizes the glass along the desired cutting path, resulting in clean and accurate cuts.

What types of glass can be cut with a Fiber Laser Glass Cutting Machine from Angel India Cad Cam Pvt. Ltd.?

These machines can cut various types of glass, including tempered glass, laminated glass, borosilicate glass, and other specialty glasses, making them highly versatile for different applications..

What are the benefits of using a Fiber Laser Glass Cutting Machine?

The benefits include high precision, speed, versatility in material cutting, durability, and a user-friendly interface. These machines are designed to enhance productivity and quality in various industries.

Does Angel India Cad Cam Pvt. Ltd. provide training for operating the Fiber Laser Glass Cutting Machines?

Yes, the company offers professional installation and training services to ensure that clients can effectively operate the machines and maximize their potential.

How does Angel India Cad Cam Pvt. Ltd. ensure the quality and reliability of its Fiber Laser Glass Cutting Machines?

Quality and reliability are ensured through a meticulous manufacturing process that includes detailed design and engineering, high-quality material selection, precision fabrication, skilled assembly, and rigorous quality testing before delivery.

.webp)

.webp)

.webp)

.webp)

.webp)