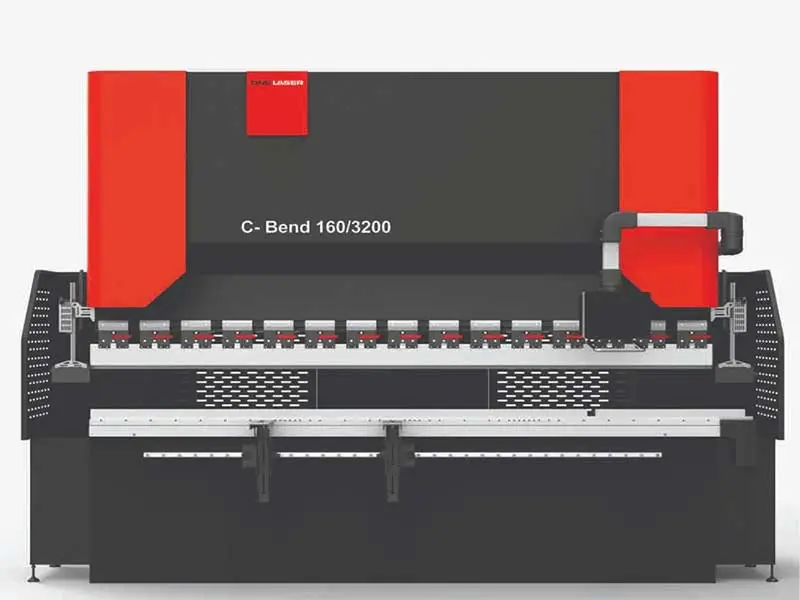

Versatility: These machines are capable of handling a variety of materials, including steel, aluminum, copper, and other alloys. The ability to work with different materials makes press brake machines versatile tools for multiple industries.

Advanced Control Systems:Modern press brake machines are equipped with advanced control systems, such as CNC (Computer Numerical Control), which enable precise programming and automation of the bending process. This technology enhances efficiency, reduces human error, and allows for complex bending operations.

Robust Construction: Angel India Cad Cam Pvt. Ltd. ensures that their press brake machines are built with robust materials and components, providing durability and long operational life. The sturdy construction also ensures that the machines can handle high-stress operations without compromising performance.

Energy Efficiency: Many of their press brake machines are designed with energy-efficient features, reducing power consumption and operational costs. This is especially beneficial for large-scale production facilities looking to minimize their environmental footprint and operational expenses.

Why Choose Angel India Cad Cam Pvt. Ltd.?

Technological Excellence: Angel India Cad Cam Pvt. Ltd. incorporates the latest advancements in press brake technology into their machines. Their commitment to innovation ensures that customers receive the most advanced and reliable products available.

Quality Assurance: The company adheres to strict quality control measures, ensuring that each machine meets high standards of performance and durability. Their focus on quality guarantees that customers receive products that deliver consistent and accurate results.

Customer-Centric Approach: Angel India Cad Cam Pvt. Ltd. prioritizes customer satisfaction by offering tailored solutions and comprehensive support. From installation and training to ongoing maintenance and technical assistance, they provide end-to-end services to ensure optimal machine performance.

Experienced Team: With a team of skilled engineers and technicians, the company ensures that each machine is crafted to perfection. Their expertise and experience in press brake technology make them a trusted partner for businesses seeking reliable bending solutions.

Applications of Press Brake Machines

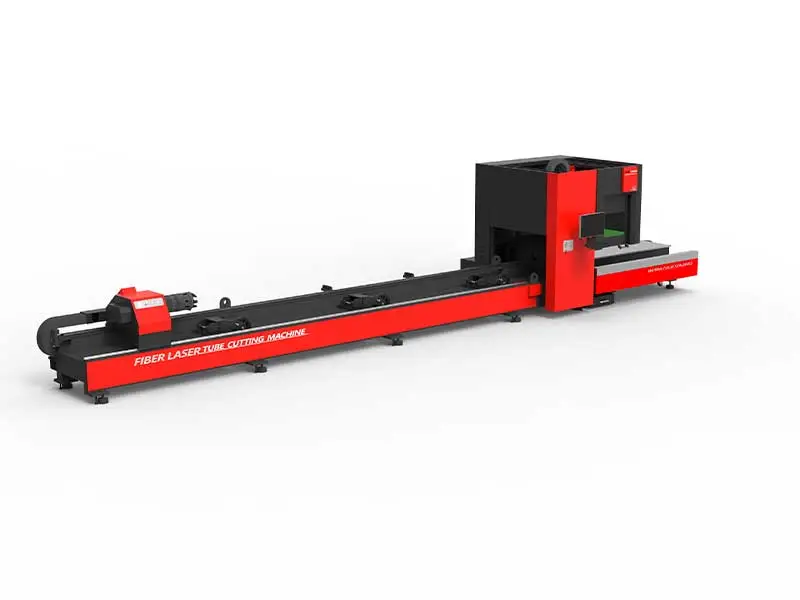

Automotive Industry:In the automotive sector, press brake machines are used to manufacture various components, such as chassis parts, brackets, and panels. The precision and versatility of these machines are crucial for producing parts that meet the industry's strict quality and safety standards.

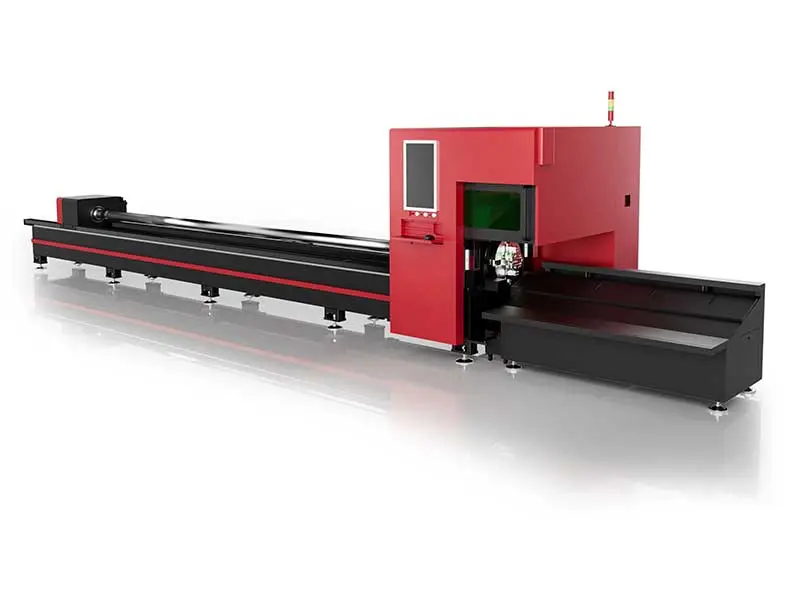

Aerospace Industry:The aerospace industry requires components with precise bends and shapes, often made from high-strength materials. Press brake machines provide the accuracy and reliability needed to produce parts for aircraft, satellites, and other aerospace applications.

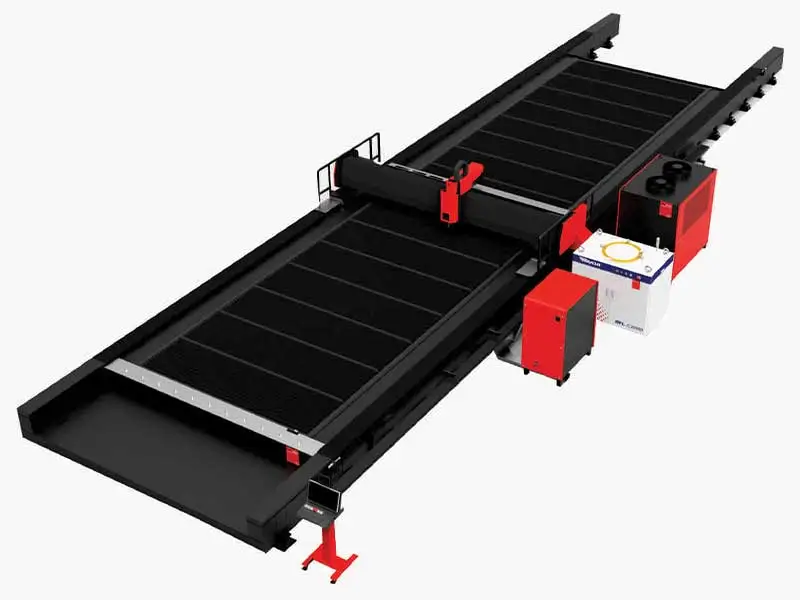

Manufacturing and Metalworking:General manufacturing and metalworking industries utilize press brake machines for producing a wide range of products, from small brackets to large panels. These machines are essential for creating components with complex geometries and precise dimensions.

Frequently Asked Questions

What materials can be bent using press brake machines?

Press brake machines can handle a variety of materials, including steel, aluminum, copper, and other alloys. This versatility allows them to be used in multiple industries, such as automotive, aerospace, construction, and manufacturing.

How does a CNC press brake machine work?

CNC press brake machines use computer numerical control to automate the bending process. The operator programs the desired bend angles, dimensions, and sequences into the machine's control system. The machine then precisely executes the bends according to the programmed instructions, ensuring high accuracy and repeatability.

What are the advantages of using press brake machines over other bending methods?

Press brake machines offer several advantages, including high precision, versatility, and the ability to handle complex bends and shapes. They also provide consistent results, reduce material waste, and improve efficiency in production processes. Additionally, advanced CNC press brakes allow for automation and reduced human error.

What maintenance is required for press brake machines?

Regular maintenance is essential to ensure optimal performance and longevity of press brake machines. This includes routine inspections, lubrication of moving parts, checking and replacing hydraulic fluids, and ensuring that safety features are functioning correctly. Following the manufacturer's maintenance guidelines and scheduling periodic professional servicing can prevent breakdowns and prolong the machine's operational life.

Are press brake machines suitable for small-scale operations?

Yes, press brake machines come in various sizes and capacities, making them suitable for both small-scale and large-scale operations. For small-scale operations, compact and lower-tonnage press brakes are available, providing the same precision and versatility as larger machines but at a scale appropriate for smaller production needs.

.webp)

.webp)

.webp)

.webp)

.webp)