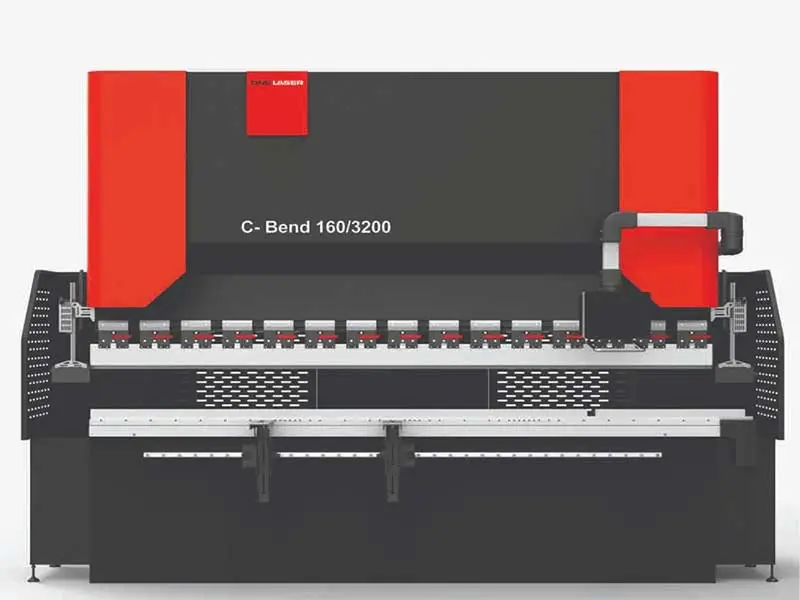

What materials can be bent using CNC hydraulic press brakes?

CNC hydraulic press brakes can handle various materials, including steel, aluminum, copper, and other alloys. This versatility allows them to be used in multiple industries, such as automotive, aerospace, construction, and manufacturing.

How does a CNC hydraulic press brake work?

CNC hydraulic press brakes use computer numerical control to automate the bending process. The operator programs the desired bend angles, dimensions, and sequences into the machine's control system. The machine then precisely executes the bends according to the programmed instructions, ensuring high accuracy and repeatability.

What are the advantages of using CNC hydraulic press brakes over traditional bending methods?

CNC hydraulic press brakes offer several advantages, including high precision, versatility, and the ability to handle complex bends and shapes. They also provide consistent results, reduce material waste, and improve efficiency in production processes. Additionally, advanced CNC systems allow for automation and reduced human error.

What maintenance is required for CNC hydraulic press brakes?

Regular maintenance is essential to ensure optimal performance and longevity of CNC hydraulic press brakes. This includes routine inspections, lubrication of moving parts, checking and replacing hydraulic fluids, and ensuring that safety features are functioning correctly. Following the manufacturer's maintenance guidelines and scheduling periodic professional servicing can prevent breakdowns and prolong the machine's operational life.

Are CNC hydraulic press brakes suitable for small-scale operations?

Yes, CNC hydraulic press brakes come in various sizes and capacities, making them suitable for both small-scale and large-scale operations. For small-scale operations, compact and lower-tonnage CNC hydraulic press brakes are available, providing the same precision and versatility as larger machines but at a scale appropriate for smaller production needs.

.webp)

.webp)

.webp)

.webp)

.webp)