Features and Benefits

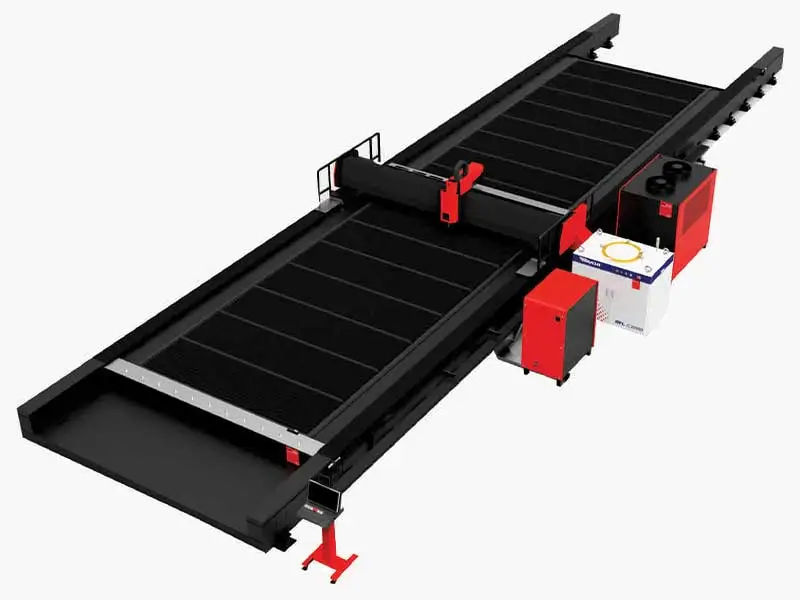

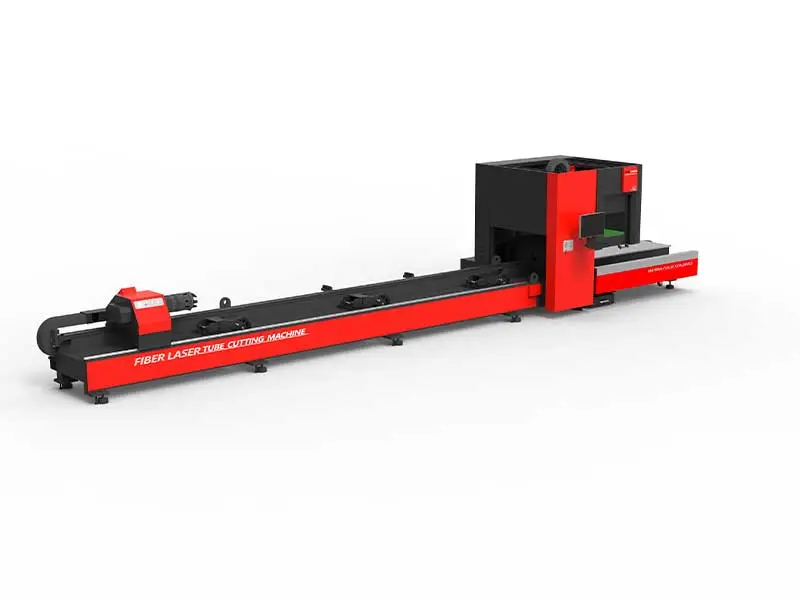

High Precision and Accuracy: The Fiber Laser Sheet Metal Cutting Machines offer unparalleled precision, making them ideal for intricate cutting tasks. The advanced laser technology ensures clean and smooth edges, reducing the need for secondary finishing processes.

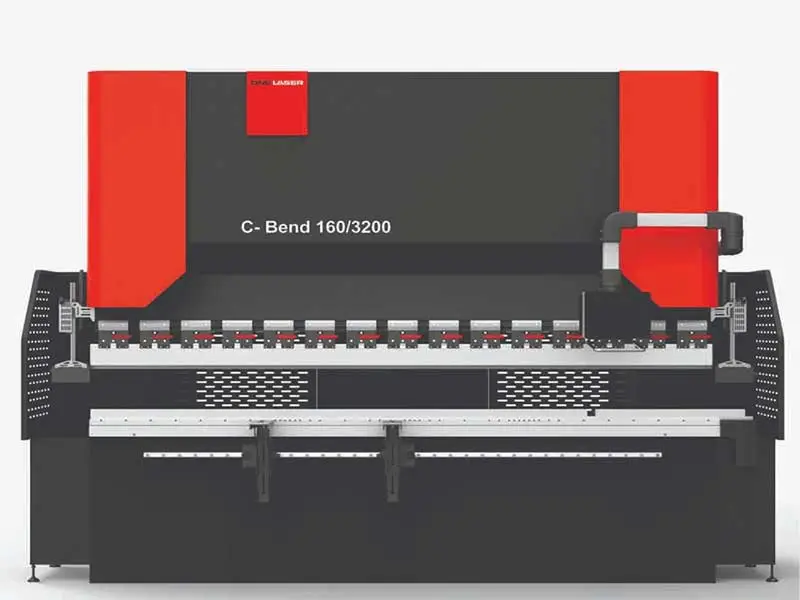

Enhanced Efficiency: These machines are designed for high-speed operations, significantly reducing production time. The efficiency of the fiber laser system translates to lower operational costs and higher productivity.

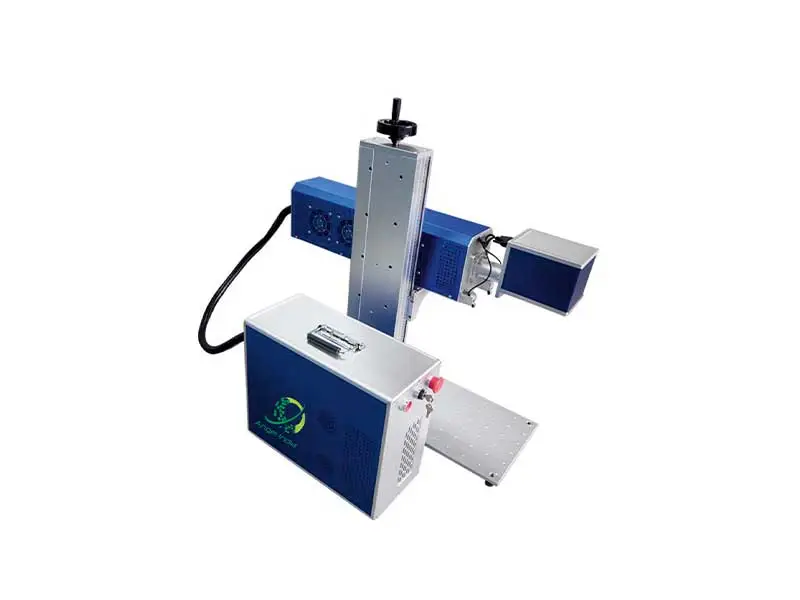

Versatility: Angel India Cad Cam Pvt. Ltd.'s fiber laser machines can cut a wide range of materials, including stainless steel, aluminum, brass, and copper. This versatility makes them suitable for various applications across different industries.

Energy Efficiency: Fiber lasers are known for their energy-efficient performance. They consume less power compared to traditional CO2 lasers, resulting in reduced energy costs and a smaller carbon footprint.

Low Maintenance: The robust design and high-quality components of these machines ensure long-lasting performance with minimal maintenance requirements. This reliability minimizes downtime and enhances overall operational efficiency.

Advantages of Fiber Laser Sheet Metal Cutting Machines

High Precision and Accuracy

Fiber laser technology offers unparalleled precision and accuracy in cutting sheet metal. The machines are capable of producing intricate designs and complex shapes with minimal tolerance, ensuring high-quality outputs. This precision is crucial for industries where exact specifications are a necessity.

Speed and Efficiency

One of the standout features of Fiber Laser Sheet Metal Cutting Machines is their speed. These machines can cut through metal at a significantly faster rate than traditional cutting methods. This increased speed not only boosts productivity but also reduces operational costs, making it an economically viable option for businesses.

Versatility

Fiber laser cutting machines are incredibly versatile. They can handle a wide range of materials, including stainless steel, aluminum, brass, and copper. This versatility makes them suitable for various applications, from heavy industrial components to delicate, intricate designs in the jewelry industry.

Cost-Effective Operation

The operational cost of Fiber Laser Sheet Metal Cutting Machines is relatively low compared to other cutting technologies. They require less maintenance, have lower power consumption, and use less material, thereby reducing overall costs. Moreover, the longevity of the fiber laser source ensures a longer operational life, providing better returns on investment.

Environmental Benefits

Fiber laser cutting is an environmentally friendly process. It produces less waste and consumes less energy compared to traditional cutting methods. Additionally, the precision of the cuts reduces the need for secondary processing, thereby minimizing material wastage.

Frequently Asked Questions

What materials can Angel India CAD CAM PVT.LTD's Fiber Laser Sheet Metal Cutting Machines cut?

The machines are versatile and can cut a wide range of materials, including stainless steel, aluminum, brass, and copper.

How do Fiber Laser Sheet Metal Cutting Machines from Angel India CAD CAM PVT.LTD improve operational efficiency?

These machines offer high cutting speeds, precision, and automation features, which collectively enhance productivity and reduce operational costs.

Are the Fiber Laser Sheet Metal Cutting Machines from Angel India CAD CAM PVT.LTD suitable for small businesses in Mumbai?

Yes, the machines are designed to cater to businesses of all sizes, offering customizable options to meet specific needs and budget constraints.

What kind of support and maintenance services does Angel India CAD CAM PVT.LTD provide in Mumbai?

The company offers comprehensive support and maintenance services, including installation, training, troubleshooting, and regular maintenance checks to ensure optimal performance.

Can Angel India CAD CAM PVT.LTD's Fiber Laser Sheet Metal Cutting Machines be customized for specific industrial applications?

Yes, the company provides customizable options to tailor the machines to specific industrial applications, ensuring that clients get the most suitable solution for their needs.

.webp)

.webp)

.webp)

.webp)

.webp)