Non-Contact Process: The laser cutting process is non-contact, meaning there is no physical force applied to the glass. This minimizes the risk of chipping, cracking, or breaking, ensuring a higher yield of usable products and reducing material wastage.

Reduced Maintenance: Fiber laser machines have fewer moving parts compared to traditional cutting equipment, resulting in lower maintenance requirements. The durability and reliability of these machines translate into longer operational life and reduced downtime.

Company Overview

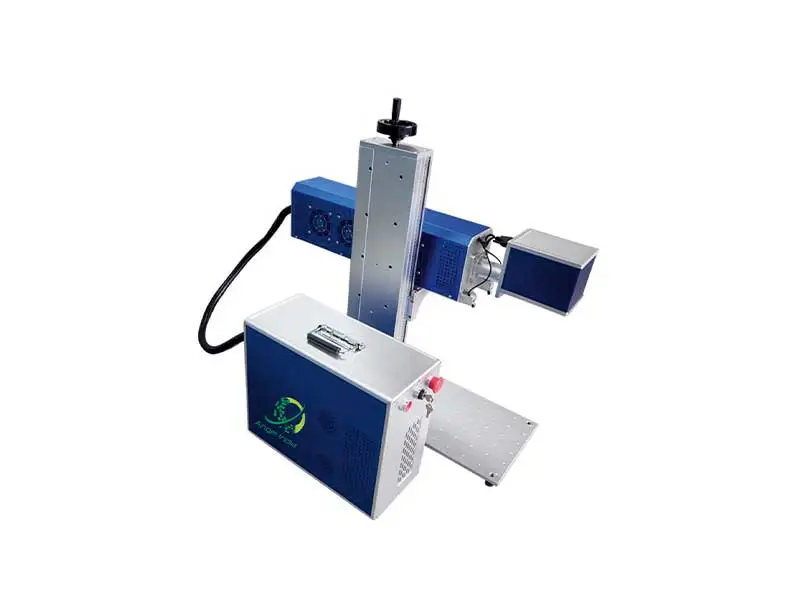

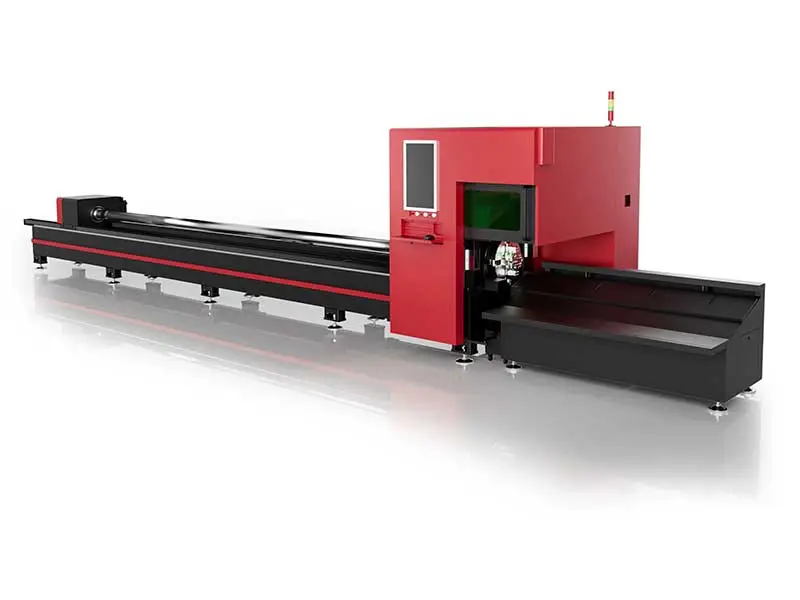

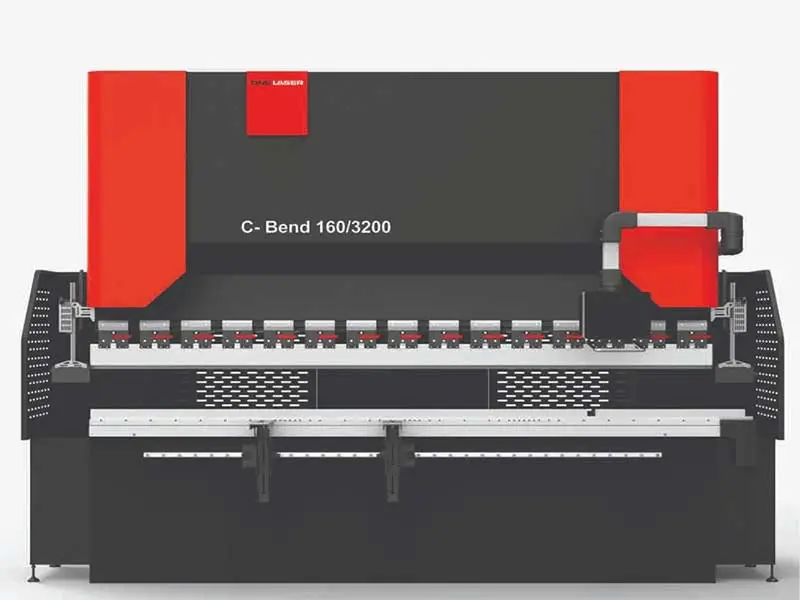

Established with a vision to revolutionize the glass cutting industry, Angel India Cad Cam Pvt. Ltd. has consistently pushed the boundaries of innovation and quality. The company boasts a state-of-the-art manufacturing facility in Hyderabad, equipped with advanced machinery and staffed by a team of skilled professionals dedicated to excellence.

Their fiber laser glass cutting machines are designed to meet the diverse needs of various industries, including automotive, electronics, construction, and interior design. By leveraging cutting-edge technology and rigorous quality control measures, Angel India Cad Cam Pvt. Ltd. ensures that every machine delivers unparalleled performance, precision, and durability.

Applications of Fiber Laser Glass Cutting Machines

Electronics and Display Panels: The electronics industry relies on precise glass components for display panels, touchscreens, and sensors. Fiber laser cutting machines can produce the high-quality, intricate glass parts needed for these applications.

Automotive Industry: In the automotive sector, fiber laser glass cutting machines are used to manufacture windshields, mirrors, and other glass components. The precision and speed of these machines ensure that automotive glass parts meet stringent safety and quality standards.

Architectural Glass: Architects and builders use fiber laser cutting to create custom glass elements for buildings, such as windows, doors, and decorative panels. The ability to produce detailed and unique designs enhances the aesthetic appeal of architectural projects.

Art and Craft: Artists and craftsmen utilize fiber laser glass cutting machines to create intricate glass artworks and decorative items. The precision and versatility of these machines allow for the creation of complex designs that would be difficult to achieve with traditional methods.

Why Choose Angel India Cad Cam Pvt. Ltd.?

Expertise and Experience: With years of experience in the industry, Angel India Cad Cam Pvt. Ltd. has developed a deep understanding of the needs and challenges of their clients, enabling them to deliver solutions that precisely meet those needs.

Customized Solutions: The company offers customized solutions tailored to the specific requirements of each client, ensuring that they get the most efficient and effective cutting solution for their particular application.

Global Reach: While based in Hyderabad, Angel India Cad Cam Pvt. Ltd. serves clients across India and around the world, providing reliable products and services on a global scale.

Innovative Edge: By continuously investing in R&D, the company stays at the forefront of technological advancements, offering cutting-edge solutions that give their clients a competitive edge.

Comprehensive Support: From initial consultation to installation, training, and ongoing support, Angel India Cad Cam Pvt. Ltd. provides a comprehensive range of services to ensure the success of their clients' operations.

Frequently Asked Questions

What types of glass can be cut with fiber laser glass cutting machines?

Fiber laser glass cutting machines can cut a variety of glass types, including tempered glass, borosilicate glass, quartz, and other specialty glasses. This versatility allows them to be used in multiple industries and applications.

What types of glass can be cut using your fiber laser glass cutting machines in Hyderabad?

Our fiber laser glass cutting machines in Hyderabad can cut a wide range of glass types, including tempered glass, laminated glass, borosilicate glass, and more. The machines are designed to handle various thicknesses and compositions, making them versatile for different industrial applications.

How does fiber laser technology improve the cutting process in Hyderabad?

Fiber laser technology offers several advantages over traditional cutting methods, including higher precision, faster cutting speeds, reduced thermal distortion, and the ability to cut complex geometries with ease. These benefits result in improved efficiency and reduced material wastage for our clients in Hyderabad.

Are fiber laser glass cutting machines suitable for mass production?

Yes, these machines are ideal for mass production due to their high-speed operation and consistent cutting quality. They can handle large volumes of work efficiently, making them suitable for industries with high production demands.

Can I get a customized fiber laser glass cutting machine for my specific needs in Hyderabad?

Yes, we offer customized solutions tailored to the specific requirements of each client in Hyderabad. Our team works closely with you to understand your needs and design a machine that meets your exact specifications, ensuring optimal performance and efficiency.

.webp)

.webp)

.webp)

.webp)

.webp)