Competitive prices: We are committed to offering our clients the best value for their investment.

After-sales service: We provide comprehensive after-sales service, including regular maintenance, spare parts availability, and technical support.

Long-term partnership: We believe in building strong, long-term relationships with our clients.

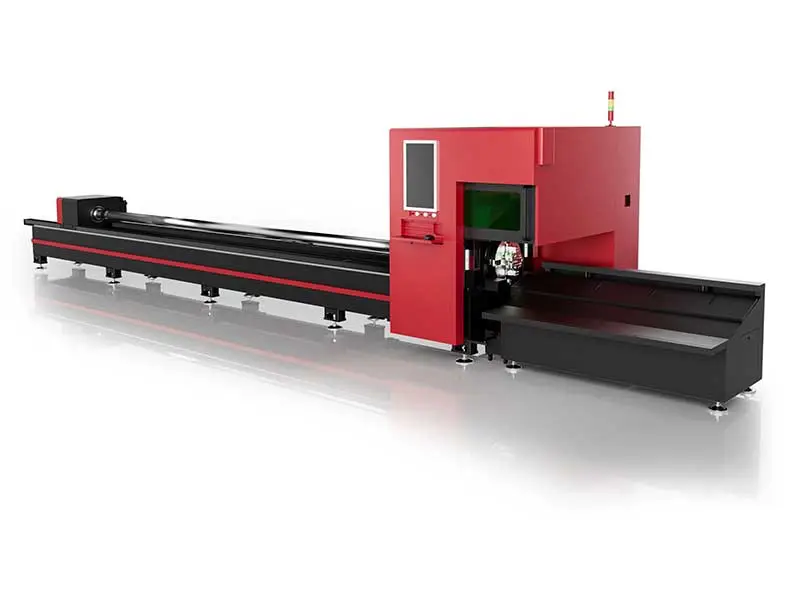

Benefits of Laser Metal Cutting

Precision Cutting: Laser cutting technology offers unparalleled precision, ensuring clean cuts with minimal heat distortion and burrs. This eliminates the need for extensive post-processing, saving time and resources.

Versatility: Laser cutters seamlessly handle a wide range of metals, including mild steel, stainless steel, aluminum, and brass. This versatility makes them ideal for diverse applications across various industries.

Speed and Efficiency: Compared to traditional cutting methods, laser cutting machines boasts significantly faster cutting speeds. This translates to increased productivity and faster turnaround times for your projects.

Material Savings: The narrow kerf width of laser cutting minimizes material wastage, leading to cost savings and reduced environmental impact.

Design Flexibility: Laser cutters can handle intricate designs with sharp corners and tight tolerances, allowing for the creation of complex and innovative metal parts.

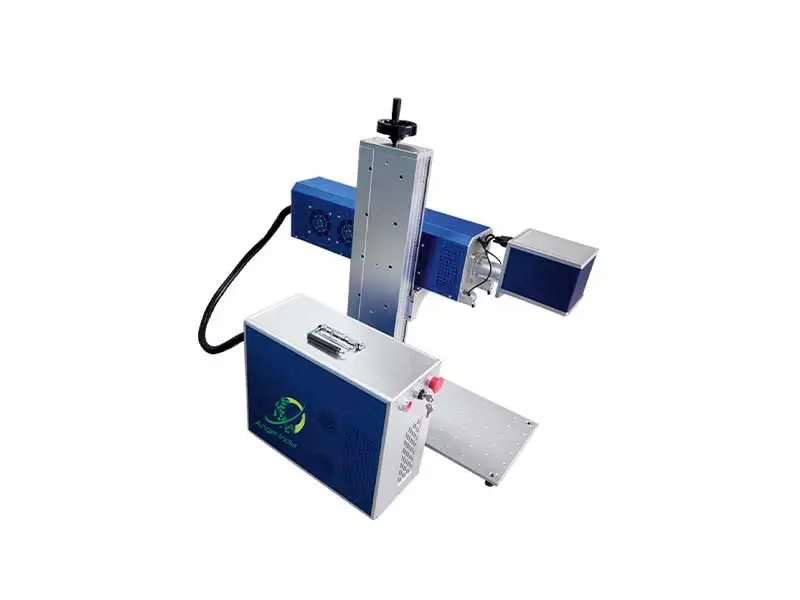

Why Choose Angel India Cad Cam?

Unwavering commitment to quality: At Angel India Cad Cam, quality is paramount. We source our machinery from reputable manufacturers and ensure stringent quality control measures throughout the entire process.

Focus on innovation: We constantly stay updated with the latest advancements in laser cutting technology and offer our clients access to the most innovative and efficient machines available.

Exceptional customer service: We prioritize building strong relationships with our clients. Our dedicated team is committed to providing exceptional customer service, from initial consultation to after-sales support.

One-stop solution: We offer a comprehensive solution for all your laser metal cutting needs, including machine selection, installation, training, and after-sales service.

Frequently Asked Questions

What types of metals can your Laser Metal Cutting Machines handle in Delhi?

Our machines can efficiently cut a wide range of metals, including mild steel, stainless steel, aluminum, brass, and more.

What factors should I consider when choosing a Laser Metal Cutting Machine?

The ideal machine for your needs will depend on several factors, including the type of metal you will be cutting, the desired cutting thickness, and your production volume. Our team of experts can guide you through the selection process.

Do you offer training on how to operate your Laser Metal Cutting Machines?

Yes, we provide comprehensive training to your operators, ensuring they can operate the machine safely and efficiently.

What kind of after-sales service do you offer?

We offer comprehensive after-sales service, including regular maintenance, spare parts availability, and technical support.

Can you customize a Laser Metal Cutting Machine to meet my specific needs?

In some cases, customization options may be available. Please discuss your specific requirements with our team to explore the possibilities.

.webp)

.webp)

.webp)

.webp)

.webp)